In the ever-changing world of engineering technology, CNC machining has emerged as a transformative force that is changing the method we produce and design complex parts with unparalleled precision. Australia is at the forefront in this technological advancement. From CNC Machines and CNC Mills.

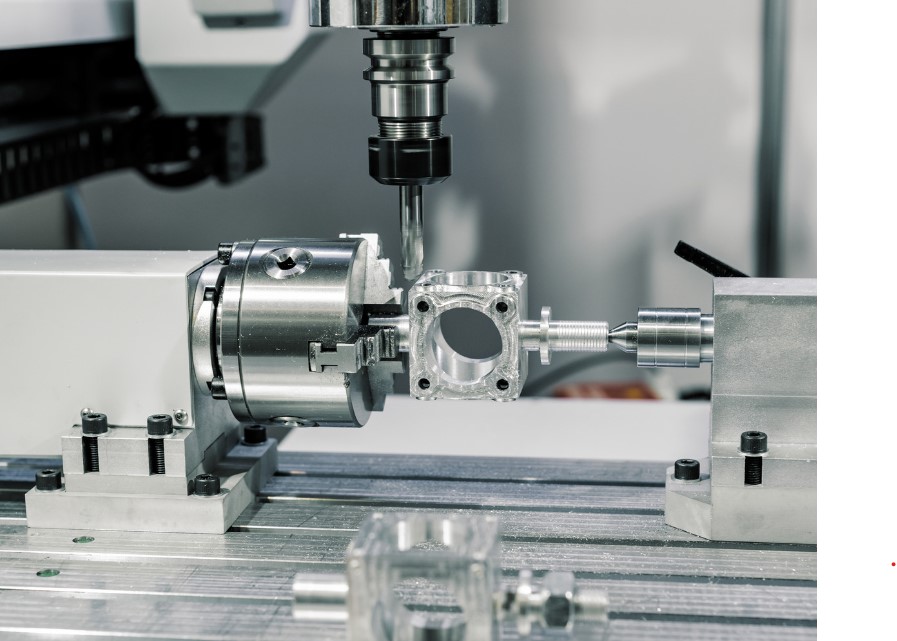

CNC machining operates by applying the principles of subtractive manufacturing. It distinguishes its self by removing material instead of adding it, to sculpt raw materials into precisely finished parts. The core of this innovation lies the CNC Machine, a marvel of technology which has become the foundation of manufacturing precision.

CNC machines use computers that are digital to monitor, automate and regulate the movements of industrial machines. This digitalized program guides the cutting blades of the machine at high speed. It transforms solid blocks of material into the exact shape you want with maximum accuracy. The integration between CNC Machines and computers is especially evident in industrial plants with large scales.

The mechanics are fascinating and complex. CNC Mills begin with a solid piece of material, and then employ high-speed cutting tools to achieve the desired shape. CNC machine is favored by industries that demand accuracy because of the precision it can achieve.

The CNC Machine industry in Australia is thriving, thanks to cutting-edge technologies and a thriving segment of the market for industrial that is driving the development of. CNC Machine Australia is a hub of technological advancements that span from aerospace to electronics and automotive harness the power of CNC machine tools for unbeatable precision and efficiency.

CNC Mills have a major impact on the future of manufacturing. They are controlled by computerized codes and can produce accurate parts for many industries. CNC Mills are essential for skilled engineers and manufacturers because of their precision and effectiveness.

CNC machining is a multifaceted procedure that has advantages above the conventional manufacturing. One of the main advantages is the ability to create parts that are extremely intricate and complex with a high degree of precision. CNC Machines can also be utilized for quick prototypes, as their digital nature allows them to be more cost-effective and time-efficient than traditional manufacturing methods.

CNC Machine Tools are an additional crucial element of the technology ecosystem. They contribute to the efficiency and effectiveness of CNC machine machining. They include a range of tools that assist in the machining process, from cutting and shaping to finishing and drilling. The combination of CNC Machines with CNC Machine Tools allows for an efficient workflow. This improves precision while minimizing waste.

Industries across the spectrum have embraced CNC machine machining due to its transformative capabilities. CNC machineries are vital in aerospace for the production of complex components that require the highest quality and reliability. CNC machining is a highly efficient way to manufacture intricate parts, like machinery and infrastructure.

CNC machining’s versatility is also demonstrated in the automotive and electronic industries. CNC machines are able to meet the requirements of both the automotive and electronic industries. CNC machineries are utilized in a variety of applications, from creating engine components to shaping intricate electronic circuits.

CNC Machines (CNC Mills), CNC Machine Tools, and CNC Machines are the pillars for this new era of technology. The power, precision, and efficiency of CNC machine tools continues to define the future of Australia and around the world. It has paved the path for innovation and excellence across every industry.